|

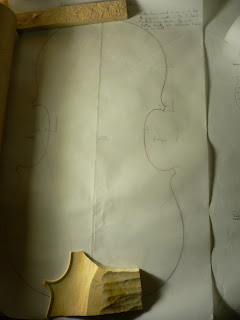

I decided to copy te "C"-bout from the bass side of the instrument, as well as the top corner. I took the bottom corner from the treble side for a matter of esthetics. I moved the centre line 2 mm in to keep the original width of the "C"-bout. For the same reason, I redrew top and bottom bouts 2 mm in as well.

I had to redraw top and bottom corners because on the original instruments the are warn.

(On the photo you can see the redrawn top corner)

I made a template from my finished drawing, made the mould and ribstructure starting with a new symmetrical outline.

Here you can see how the linings are jointed in the corner blocs, the same way as for the violin.

Finished ribstructure!

This is a practice piece I made to try out a new technique I was told about by Thomas Bertrand. I carved the fluting first, right up to the edge, so the edge had to be left higher than the final edge thickness.

On old Cremonese instruments, the edge doesn't have the same thickness everywhere. It is thickest at the 4 corners, then is is a bit lower in the "C"-bout and it is the lowest in top and bottom bouts.

In the first year, we just market the different edge thicknesses with the marking gauge, made a flat purfling platform and then made purflind and fluting and arching.

But, when making the fluting up to the edge, this phenomen appears automatically because the fluting is deeper in top and bottom bout than in the "C"-bout, and the fluting going up to notthing in the corner, makes it automatically the highest point.

I had to choose one gouge to do the whole fluting, and determine the edge thickness to start with.

I finally decided to use 3 gouges with the same curve but different widths (sweep 5) and determined 6 mm as edge hight. When the purfling was put in, and the edgework was done, I had a final edge thickness of 5,5 mm on the corner, 5 mm in "C"-bout and 4,5 mm in bottom bout. Which is exactly what I wanted!

The main reason why I wanted to try out this new method is because I think you get a fluting and an edgework that look much more natural that way. The curve of the edgework cuts the curve of the fluting and that way, you get an absolutely clean and sharp edge. At the same time the fluting looks like it never wants to stop which gives a powerfull start for the arching.

Here you can see how the edge becomes naturally thicker at the corner.

Using the ribs and locating pins, I drew the outline on front and back (overhang = 2,8 mm).

With the marking gauge, I marked the edge thickness of 6 mm all around the plates and carved the rough arching starting from the gauge mark. Then, using the ribstructure as a reference I finished the outline and corners.

Here you can see the finished outline of the back.

Rough arching on the front.

I start the fluting together with the arching.

Here you can see the arching starting from the fluting which makes it look like one natural shape.

Arching and fluting.

As long as the fluting doesn't have it's final depth, I leave a very small flat on the edge. I compare the fluting with the one on the practise piece.

Here you can compare my outline and corners to the photos of the original instrument.

I use a plaster cast of the original front as a reference when carving the arching.

No comments:

Post a Comment